Precision and clarity matter in fields where even the smallest miscalculation can lead to costly errors. Technical drawings serve as the foundation for industries that rely on visual plans, ensuring that products, structures, and systems function as intended. From automotive design to aerospace engineering, technical drawings are the blueprint for innovation. But which industries depend on them the most? Let’s take a closer look.

What Sets Technical Drawing Apart From Other Forms of Illustration?

Not all drawings are created equal. While an artist might sketch a landscape for inspiration, technical drawing is about conveying precise information. Unlike freehand sketches, these drawings follow strict conventions, using standardized symbols, measurements, and projections to communicate details effectively. Every line, angle, and notation serves a functional purpose, allowing engineers, architects, and manufacturers to interpret designs with absolute clarity. The ability to create accurate, scalable, and detailed drawings is what makes technical drawing an essential tool in industries that require precision. It’s the difference between an idea and a fully realized, working product.

How Designers Capture the Precision and Artistry of Cars

Automotive design is more than just sleek curves and aggressive styling—it’s a balance between aesthetics and engineering. Every vehicle, whether a luxury sports car or a fuel-efficient sedan, begins its journey on paper. Drawing cars requires designers to translate ideas into detailed schematics, incorporating aerodynamics, structural integrity, and mechanical functionality into their work. These drawings guide the manufacturing process, ensuring that everything from the frame to the electrical systems aligns perfectly. Without detailed schematics, the transition from concept to production would be impossible. It’s not just about making cars look good—it’s about making them perform flawlessly.

The Aerospace Industry is Built on Technical Drawings

When designing aircraft, there’s no room for guesswork. Every component, from the fuselage to the engine, must be drawn with meticulous detail before production even begins. Aerospace engineers use technical drawings to illustrate everything from aerodynamics to structural reinforcements, ensuring that planes, helicopters, and spacecraft meet strict safety and performance standards.

These blueprints guide manufacturing teams through assembly, allowing them to work with pinpoint accuracy. Even after an aircraft is built, technical drawings remain critical for maintenance, repairs, and modifications, ensuring that every adjustment adheres to original specifications.

Architects Turn Concepts Into Functional Buildings

Architecture is a blend of creativity and structural engineering, and technical drawings serve as the bridge between concept and construction. Whether designing a residential home or a skyscraper, architects rely on detailed floor plans, elevations, and sections to communicate their vision to builders. These drawings provide measurements, material specifications, and construction details that contractors and engineers use to bring designs to life.

Beyond aesthetics, architectural drawings also account for structural integrity, plumbing, electrical systems, and environmental factors, ensuring that every aspect of a building is planned with precision. Without these detailed schematics, construction projects would lack the necessary guidance to ensure stability, safety, and efficiency.

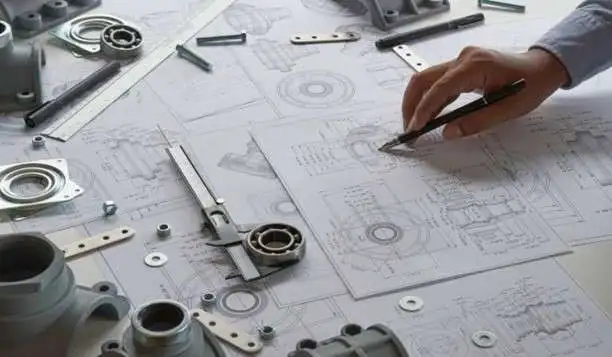

Manufacturing is Dependent on Technical Drawings

Factories don’t produce products based on vague instructions. In the manufacturing industry, technical drawings dictate everything from dimensions to assembly processes. Whether it’s consumer electronics, heavy machinery, or medical devices, manufacturers rely on detailed schematics to ensure consistency and quality control.

These drawings provide step-by-step assembly instructions, guiding production teams through fabrication, machining, and final assembly. With automation and robotics becoming more prevalent, technical drawings also serve as the programming foundation for CNC machines and 3D printers, ensuring that each component is crafted to exact specifications. The result? Products that meet stringent industry standards without costly rework.

Civil Engineers Use Technical Drawings for Infrastructure Projects

From bridges to highways, civil engineering projects depend on precise planning to ensure safety and durability. Technical drawings outline every detail of an infrastructure project, from structural reinforcements to drainage systems. Engineers use them to map out construction phases, calculate load-bearing capacities, and coordinate between various teams working on the same project.

Without these detailed schematics, projects could face delays, cost overruns, and structural failures. Whether it’s laying out a city’s transportation grid or designing a flood-resistant dam, technical drawings are the backbone of successful civil engineering projects.

The world of technical drawing has many applications. From designing new cars that are both beautiful and aerodynamic to manufacturing applications, these drawings are essential for their precision. It turns creativity into technical models that come to life in powerful and noticeable ways.

Keep an eye for more latest news & updates on Internal Insider!