Your supply chain is one of the most important infrastructural components for the ongoing productivity and performance of your organization. When it’s running smoothly, it can empower your organization, minimize time waste, and allow you to reach peak productivity. But even a minor disruption can cause chaos – at least for unprepared businesses.

Supply chain management is both a proactive and reactive solution to this problem, but it’s not always easy to execute. Why do supply chain management strategies fail?

Supply Chain Management: The High-Level Vision

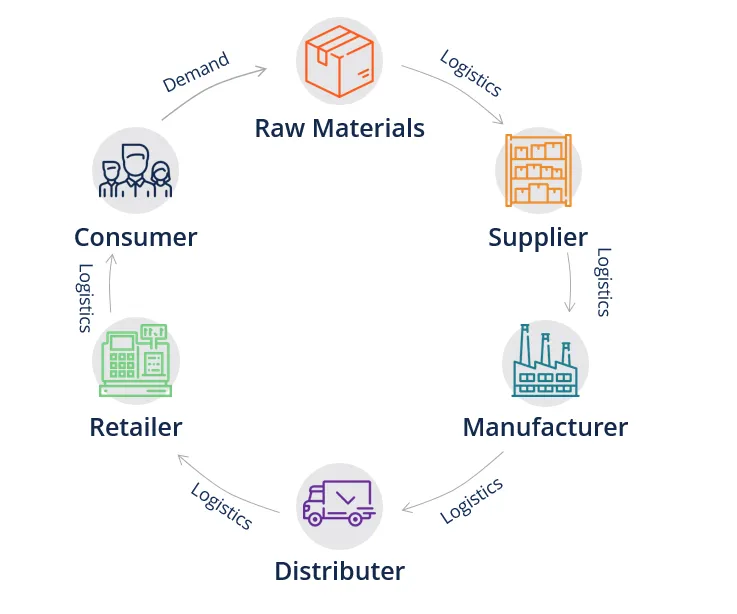

Supply chain management is all about carefully controlling the nodes and interactions within your supply chain to better serve the goals of your organization. This includes things like vetting and selecting vendors, managing partnerships, facilitating better external and internal communication, mitigating risks, and monitoring KPIs to identify opportunities for further improvement.

Obviously, there’s a lot here. Already, you can see why so many organizations insufficiently pursue supply chain management: there are too many variables to work with. These are not easy problems to prevent or solve.

This is why so many businesses hire supply chain management strategists to help them build and execute a better supply chain management strategy. Supply chain management experts have specialized experience in such matters and can usually spot and prevent issues better than your organization. These outsourced experts also have the advantage of being third parties; because they’re outside your organization, they can more easily see things that are beyond your blind spots.

The Many Modes of Supply Chain Failure

One simple answer to why supply chain failures happen is because there are so many ways in which supply chains can fail. Vendors can collapse. Transportation elements can fail. Entire industries can be compromised. Internal systems can cause complications. Any single node or interaction between nodes in the supply chain can cause a disruption – and disruptions can spiral into complexity even in the simplest supply chains due to the intermingling of various variables.

How Most Supply Chain Management Strategies Fail

These are some of the most common ways that supply chain management strategies fail.

· Sourcing strategies. Sometimes, supply chains fail because of inadequate sourcing strategies. You might choose vendors that can’t keep up with your level of demand. You might choose vendors with inconsistent offerings. You might choose vendors in unsuitable locations, where local turmoil can interfere with availability. The list goes on and on. Due diligence can prevent many of these issues, but there’s only so much you can do.

· Demand and supply planning. If you want your supply chain to work adequately, you also need to plan around supply and demand in your own business – as well as supply and demand for all your partners. Even the best economists in the world struggle to make such economic predictions, so it’s understandable why supply chains fail in this regard.

· Natural disasters. Even if you somehow manage to perfectly predict the general course of supply and demand, your supply chain may be disrupted by natural disasters. A single hurricane, tornado, or earthquake could preclude your vendors from doing their jobs or interfere with the logistical networks necessary to get their goods to you.

· Market conditions. Infamously, the COVID-19 pandemic disrupted supply chains all over the world. This was partially due to the pandemic and subsequent lockdowns themselves, but it was also partially due to generally unfavorable market conditions. Major economic downturns and disruptions can throw a wrench into your supply chain plans.

· Tech issues. Most businesses rely on software to manage and coordinate their supply chains. This has been a great leap forward in terms of total productivity, efficiency, and even troubleshooting, but it also introduces a new vulnerability. If your tech infrastructure isn’t sufficient for your needs, if it isn’t a good fit, or if it frequently stops working, it’s going to cause major supply chain issues on your end.

· Internal efficiency problems. Sometimes, the problems with supply chains are primarily due to internal efficiency imperfections. If you’re not handling materials or communications efficiently and consistently, it can prevent you from managing your supply chain well.

· Supply chain fragmentation. Supply chain fragmentation isn’t necessarily a bad thing. Sometimes, it can help you decentralize your supply chain and work with the individual components more easily. But fragmentation can also lead to trouble with coordination and predictability.

As you can see, you may not have full control over all these variables, and some of them can affect your business regardless of whether you acknowledge them or control for them. No supply chain management strategy is perfect, and even if one could be, there are so many variables outside of your control that imperfections and disruptions would still occur. Still, it’s in your best interest as a business owner to be as proactive and risk averse as possible in your supply chain management strategy.

Keep an eye for more latest news & updates on Internal Insider!