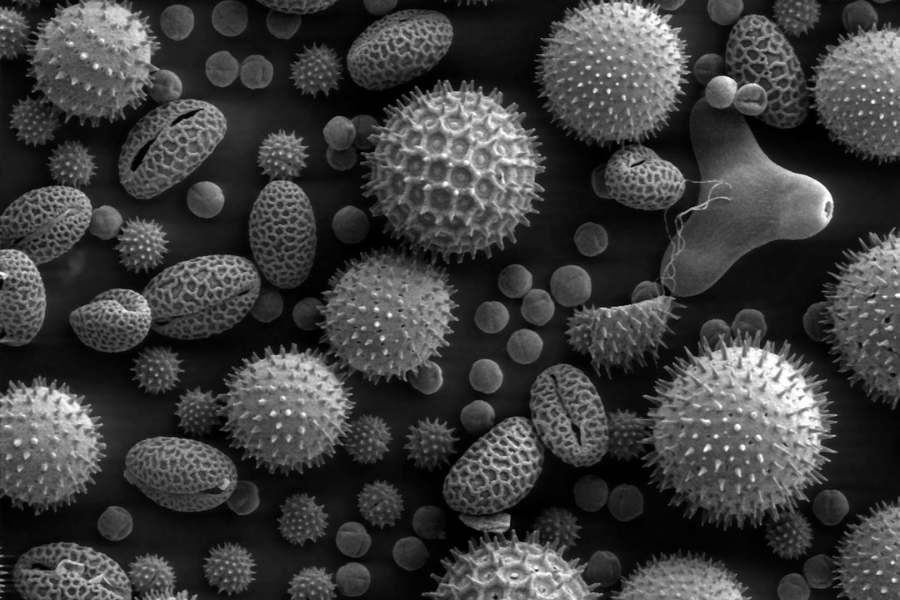

Scanning Electron Microscopy, also known as SEM is an imaging tool that enables the visualization of minuscule details, in materials at high magnifications with exceptional clarity and depth. Unlike microscopes like the compound microscope SEMs utilize electrons instead of light to produce images.

While basic microscopes allow for sample observation in their colors under a lens in open air or water they are limited by the wavelength of light restricting magnification and depth of field within a defined range. In contrast scanning electron microscopy offers depth of field and higher magnifications than optical microscopy making it a potent research instrument.

By incorporating spectroscopic methods for chemical analyses SEMs provide capabilities and unveil surface intricacies at nanoscale resolution. Often just a single greyscale image obtained through scanning electron microscopy is sufficient to meet research objectives by facilitating the visualization of microstructures, within material samples.

Understanding the Fundamentals of Scanning Electron Microscopy

In Scanning Electron Microscopes (SEMs) images are generated by directing a beam of high energy electrons, towards a sample and moving it in a zig pattern. This process involves components working in tandem:

- Condenser and objective lenses; Focus the electron beam.

- Deflector coils; Alter the direction of the beam.

Within the sample chamber typically three detectors are positioned at angles:

- X ray detector; Identifies X rays emitted from the sample.

- scattered electron detector; Detects electrons that rebound off the sample.

- Secondary electron detector; Recognizes electrons released from the surface of the sample.

Unlike microscopy methods SEM does not necessitate thin samples as it does not rely on light passing through them. Magnets aid in concentrating the electron beam into a point a few nanometers wide. When this focused beam strikes the surface of the sample it generates signals that are captured by detectors. These signals are then used to produce high resolution images and perform measurements.

SEMs can identify:

- Backscattered electrons; Offering insights, into the shape, surface characteristics and composition of samples.

- Electrons; Revealing details of surface topography.

By employing these techniques scanning electron microscopy (SEMs) are able to generate images, at the nanoscale.

What Sets Electron Microscopy Apart From Microscopy?

The main distinction lies in the types of beams used. Electron Sems utilize a stream of electrons of light. Positioned at the microscopes apex, an electron source emits a electron beam.

Sems Feature Three Electron Sources

1. Thermionic filament – This involves heating a tungsten filament within the microscope to emit electrons. Operating at temperatures the tungsten filament gradually evaporates over time and can eventually break, potentially contaminating the upper part of the electron column. On average a tungsten source lasts around 100 hours, contingent on vacuum conditions.

2. Field emission gun (FEG) – This mechanism generates an field that extracts electrons from their atoms. It is often favored in SEMs for producing high resolution images. Necessitates a vacuum setup that can be costly.

3. Cerium Hexaboride cathode (CeB6) – Known for providing ten times brightness than tungsten sources resulting in improved signal to noise ratio and resolution quality. A CeB6 source typically offers, over fifteen times the lifespan of tungsten sources; exceeding 1500 hours. The desktop Phenom SEM series exclusively utilizes CeB6 sources.

Applications Of Sems

The use of Scanning Electron Microscopes (SEMs) spans across sectors such, as industry, commerce and research.

In the dominion of materials science SEMs play a role in activities like research, quality assurance and failure analysis. The advancements in modern materials science heavily rely on SEMs for studying nanotubes, nanofibers, high temperature superconductors, mesoporous structures and alloy strength.

Industries related to material science including aerospace, chemistry, electronics and energy have greatly benefited from the contributions of SEMs.

Researchers are investigating into approaches to utilize nanowires as gas sensors by enhancing fabrication techniques. Electron microscopy is instrumental in characterizing nanowires and unraveling their gas sensing capabilities.

For semiconductor assessment purposes accurate topographical data is essential for ensuring performance. SEMs provide resolution three images that facilitate precise measurements of semiconductor composition.

SEMs are indispensable in wafer manufacturing processes as one of the tools, for quality control. Larger monitors have been found to alleviate fatigue among inspectors during quality checks.

The manufacturing of microchips is increasingly turning to scanning electron microscopes (SEMs) to better understand the efficiency of production techniques and materials. With the miniaturization and complexity of materials, along with the use of intricate self assembling polymers the detailed three dimensional capabilities of SEMs are crucial for microchip development and manufacturing.

As the Internet of Things (IoT) becomes more integrated into life for consumers and industries SEMs will play a role in creating affordable energy efficient chipsets, for unconventional computing devices and interconnected gadgets.

Keep an eye for more news & updates on InternalInSider!