In the modern industrial landscape, precision is paramount. From construction and automotive manufacturing to aerospace and electronics, the demand for finely crafted metal components has never been higher. This article explores the critical role of reliable sheet metal cutting services and how they empower businesses to achieve new heights of innovation and efficiency.

What is Sheet Metal Cutting?

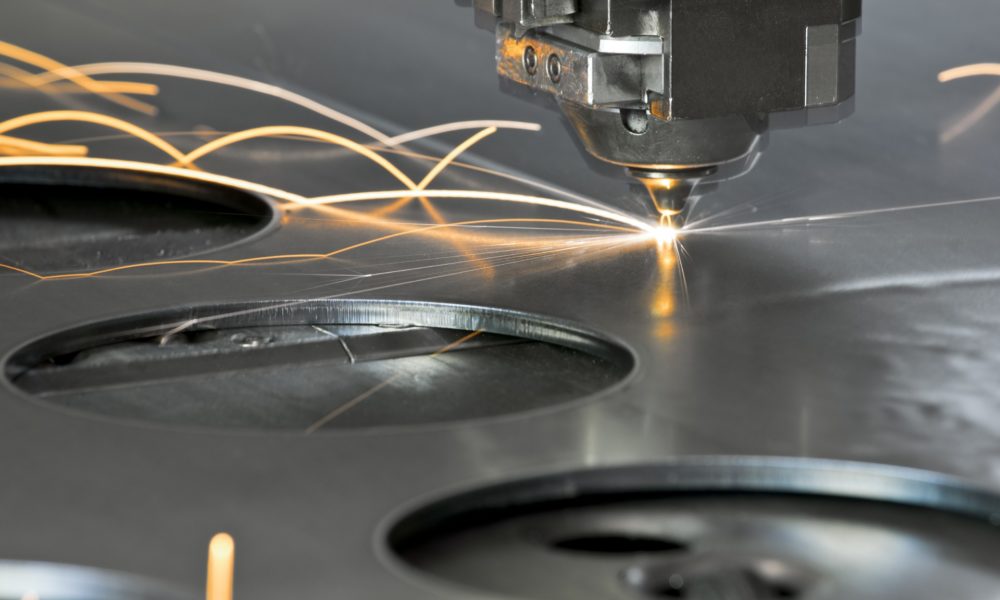

In the manufacturing industry, sheet metal cutting is a fundamental process that entails shaping, cutting, and forming metal sheets into desired configurations. It encompasses various techniques, each suitable for different types of metals and application requirements. The most common methods include laser cutting, plasma cutting, and waterjet cutting. These technologies have revolutionized how industries handle metal, allowing for more intricate designs and faster production times.

Why Reliable Metal Cutting Services Matter

Choosing the right service provider is crucial for any project that involves sheet metal cutting. Reliable sheet metal cutting services not only ensure precision but also contribute to cost efficiency, project timeliness, and overall product quality. Here’s why reliability in metal cutting services is non-negotiable:

Precision and Accuracy

Highly accurate cuts are essential for components that must fit precisely into complex assemblies. Reliable services utilize advanced technology to ensure that each cut meets stringent specifications without compromise.

Material Efficiency

Efficient use of materials is vital for cost control and environmental sustainability. Skilled providers can maximize yield from each sheet, reducing waste and lowering material costs.

Scalability and Flexibility

Whether for a single prototype or mass production, dependable services can scale operations to meet client demands. Flexibility in handling various metals and thicknesses also allows businesses to explore new designs and applications.

Rapid Turnaround Times

In industries where time is money, the ability to deliver quickly is invaluable. Reliable cutting services streamline their processes to shorten lead times, helping clients bring products to market faster.

Enhanced Safety

Proper handling and cutting of metal sheets reduces the risk of workplace accidents. Established service providers prioritize safety protocols, protecting their employees and clients’ interests.

Key Applications of Sheet Metal Cutting Services

Automotive Industry

The automotive sector uses sheet metal cutting to create everything from chassis parts to intricate engine components. Precision cutting ensures parts perform reliably under extreme conditions.

Construction and Architecture

Architects and builders rely on cut metal for structural elements, decorative panels, and bespoke fixtures. Laser-cut designs, in particular, offer both aesthetic appeal and structural integrity.

Aerospace and Aviation

The aerospace industry requires components that are both lightweight and strong. Precision metal cutting is crucial for fabricating parts that meet these critical standards.

Electronics and Technology

As devices become smaller and more complex, the need for precisely cut metal parts increases. Metal cutting services provide the necessary precision for components like enclosures and heat sinks.

Choosing the Right Metal Cutting Partner

When selecting a metal cutting service, consider their technology, expertise, capacity, and track record. A provider that invests in the latest technology and has a proven history of satisfying client specifications is more likely to deliver quality results. Additionally, look for services that offer consultation and collaborative planning to ensure your project’s success.

For those in need of reliable sheet metal cutting services, it’s essential to choose a partner that understands the intricacies of your industry and can adapt to complex requirements. With the right partner, businesses can not only achieve high-quality results but also innovate and expand in their respective markets.

Conclusion

Reliable sheet metal cutting services play a crucial role in modern manufacturing. They are the cornerstone upon which businesses build their products, ensuring precision, efficiency, and safety. By investing in high-quality metal cutting solutions, industries can push the boundaries of what is possible, turning visionary designs into tangible products that drive progress and prosperity. For more insightful articles on industry trends and innovations, visit Daily Post, your go-to Australian website, for the latest news and updates.

Stay in touch to get more updates & news on internalinsider