Introduction

Battery test rooms are specialized rooms in which batteries are tested to ensure proper operation and safety. These structures can create extreme heat or cold, cool or dry areas, and even simulate vibration or elevation. This helps manufacturers test batteries under extreme conditions, ensuring they won’t fail in real-world use or cause safety issues.

The room has many special features. A temperature control system can heat or cool a room to a specific temperature. A humidity control system can make the air very humid or dry. Battery Charging and Discharging The system can charge or discharge the battery according to the test schedule. The real-time monitoring system monitors battery performance and safety during testing.

The testing process is straightforward:

- The test is prepared by determining the desired temperature, humidity, and test parameters.

- The battery is inserted and connected to the charging and discharging system.

- The test begins with the building simulating conditions as it charges or discharges the battery.

Real-time monitoring monitors performance and safety during testing.

After testing, the data is analyzed to evaluate battery performance and identify potential problems. By testing batteries in these buildings, manufacturers can ensure their products meet safety and performance standards, giving consumers confidence in their devices and vehicles. Read more

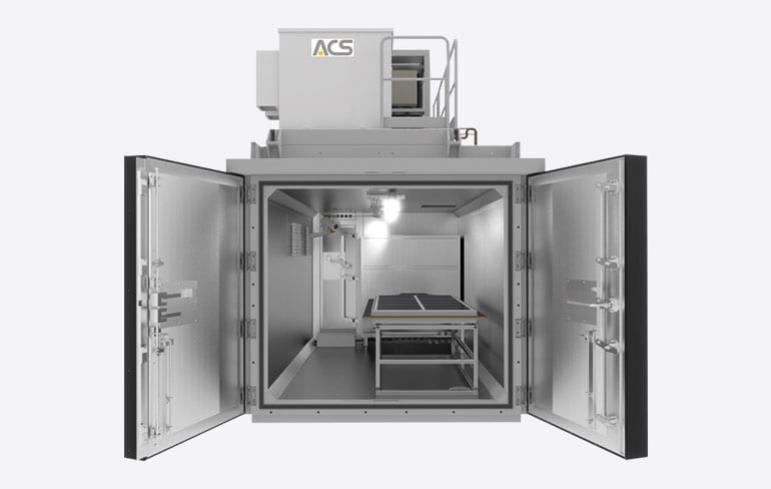

Components of a Battery Test Chamber

A typical battery test chamber consists of the following components.

Temperature control system

- Controls temperature from -70°C to 150°C

- Simulate extreme temperatures, such as desert heat or arctic cold

- Be sure to control the temperature accurately, usually within ±1°C

Humidity management system

- Keep the humidity between 10% and 90%.

- Imitate wet environments, such as rainforests or arid deserts.

- Be sure to maintain humidity accurately, usually within ±1%.

Battery charging and discharging system

- Charge and discharge battery sedge test protocols not.

- Simulate real-world applications, such as charging phones or electric cars.

- Ensure that charging and discharging rates are adhered to exactly.

Real-time monitoring systems

- Check battery performance, temperature, and humidity during testing.

- Provide real-time data, usually on a computer screen or dashboard.

- Helps identify potential problems or deficiencies in testing.

Safety Measures

- Emergency stop buttons: Stop the test immediately if something goes wrong

- Temperature restriction: Prevent overheating or overcooling

- Ventilation system: Eliminates hazardous gases or fumes

- Ensure proper operation and prevent accidents or injuries

These features create a complete battery test environment, simulate real-world conditions, and ensure accurate and reliable test results.

How Does a Battery Test Chamber Work?

Step 1: Test preparation

Setting the desired temperature and humidity levels, configuring battery charging and discharging schedules, and calibrating the monitoring system ensure accurate test conditions and measurements.

Step 2: Insert the battery

The battery is installed in the housing and connects to the charging and discharging system. Secure connections are essential to prevent damage or security issues.

Step 3: Testing

The chamber simulates various environmental factors, such as temperature intensity and heat level, while charging and charging according to battery test programs Real-time monitoring of performance and safety data, including temperature, including temperature, energy and current.

Step 4: Data analysis

Test data are analyzed to evaluate battery performance, identify potential problems, and optimize the system. This includes reviewing heating and humidity levels, battery voltage and capacity, and charging and discharging rates. By analyzing this data, manufacturers can improve battery performance, safety, and reliability.

Types of Battery Testing

Battery test chambers perform various tests, including:

Heat control on a bicycle

- Simulate extreme temperature changes, such as desert heat to arctic cold.

- Test battery performance and durability for temperature fluctuations.

- Helps identify potential problems, such as overheating or overcooling.

Humidity test

- Evaluate battery performance in very humid environments, such as tropical rainforests.

- Simulates water exposure to test battery durability and resistance.

- Helps identify potential issues, such as water stains or water damage.

Vibration test

- Simulates mechanical pressures and vibrations, such as driving on steep roads.

- Test the battery for stability and resistance to movement and shock.

- Helps identify potential issues, such as content damage.

Theory of Higher Things

- Test battery performance as if at high altitude, hills.

- Simulates low air pressure and oxygen levels to test battery capacity.

- Helps identify potential problems, such as decreased performance or overheating.

These tests help ensure the battery meets quality and safety standards and withstand various environmental conditions. Manufacturers can identify potential issues and improve battery design and performance by creating real-world scenarios.

Benefits of Battery Test Chambers

Battery test chamber ensures:

Advanced security

- Identifies potential safety hazards, such as overheating or explosion hazards.

- Mitigate risk by testing batteries in simulated real-world conditions.

- Make sure the battery meets safety standards, reducing the risk of accidents or injuries.

Improved performance

- Optimizes battery design for efficiency and reliability.

- Test batteries under extreme heat, humidity, and vibration.

- Improve overall battery life and performance.

Costs have been reduced

- Streamline the testing and development process, saving time and resources.

- Reduces the need for expensive and time-consuming field testing.

- Helps manufacturers avoid costly recalls or redesigns.

Compliance

- Comply with regulatory standards, such as UL and IEC certification.

- Meet industry requirements as set by automotive and consumer electronics companies.

- Ensure that batteries meet international safety and performance standards.

Battery test kits ensure safety and improve efficiency and reliability. This results in reduced costs and better products for consumers.

Conclusion

A battery test laboratory plays a vital role in the reliability and safety of batteries. By understanding how these structures work and their tests, manufacturers can improve battery efficiency and performance and reduce costs. Remember that a well-designed battery test room is critical to the success of your battery-powered products.

Stay in touch with us for more updates and alerts! internalinsider.