In the world of modern manufacturing, precision is everything. Whether producing packaging, automotive parts, or intricate electronics, the role of a steel rule die maker has never been more crucial. This blog post will explore the intricate art and science behind steel rule die making, shedding light on why it’s an indispensable skill in today’s industry. By the end, you’ll understand the process, applications, and significance of steel rule dies, especially if you’re a business owner or professional in the manufacturing sector.

What is a Steel Rule Die?

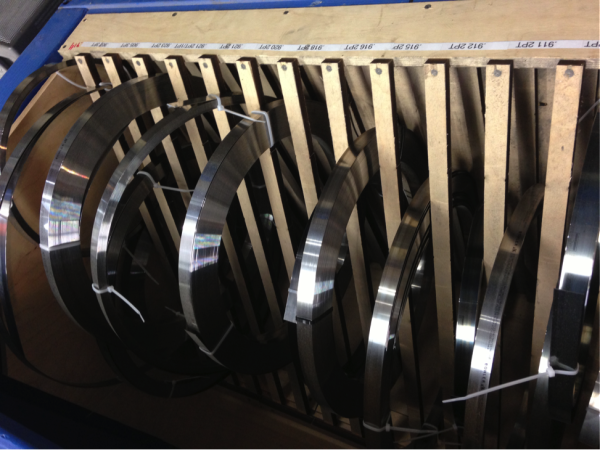

Steel rule dies are essential tools in the manufacturing industry, used for cutting and shaping materials with high precision. These tools consist of a flat base and a sharpened steel blade, bent into custom shapes and mounted onto the base. The versatility of steel rule dies makes them suitable for various applications, from packaging to automotive components.

Historically, steel rule dies have evolved significantly. Early forms of die cutting were rudimentary and lacked the precision we see today. Advances in technology and engineering have transformed steel rule dies into the precise instruments they are now, capable of producing intricate and accurate cuts.

Understanding the role and importance of steel rule dies is crucial for anyone involved in manufacturing. These tools enable efficient production processes, reduce waste, and ensure consistency in the final products.

The Process of Making Steel Rule Dies

Creating a steel rule die involves several meticulous steps, starting with design and ending with the final assembly. The first step is designing the die, which requires a detailed understanding of the material to be cut and the desired outcome. Designers use specialized software to create accurate blueprints.

Once the design is finalized, the next step is to cut the steel rule to match the design. This process involves using high-precision machines to ensure that the steel rule is bent and shaped correctly. Accuracy is paramount at this stage, as even minor deviations can affect the die’s performance.

The bent steel rule is then mounted onto a flat base, typically made of plywood or similar material. This base provides stability and support, ensuring that the die can withstand the pressures of cutting without deforming. The final step is to inspect the die for any imperfections and make necessary adjustments.

Types of Steel Rule Dies

There are several types of steel rule dies, each designed for specific applications. Flatbed dies are commonly used for cutting thicker materials, such as cardboard and foam. These dies offer high precision and can produce clean cuts even with dense materials.

Rotary dies, on the other hand, are used for cutting thinner materials, such as paper and plastic films. These dies are mounted on a cylindrical base and are rotated during the cutting process. Rotary dies are ideal for high-speed production lines, where efficiency is crucial.

Combination dies incorporate features of both flatbed and rotary dies, offering versatility and flexibility. These dies are suitable for various applications, allowing manufacturers to switch between different cutting processes without changing tools.

Materials Cut with Steel Rule Dies

Steel rule dies can cut a wide range of materials, making them incredibly versatile. Commonly cut materials include paper, cardboard, plastic, rubber, and foam. Each material requires specific considerations to ensure clean and accurate cuts.

For example, cutting paper and cardboard is relatively straightforward, requiring a sharp blade and moderate cutting pressure. However, cutting plastic and rubber can be more challenging, as these materials can be tough and resistant. Specialized blades and higher cutting pressures are often needed to achieve clean cuts.

Foam is another material often cut with steel rule dies. Cutting foam requires careful consideration of the die’s design, as the material can compress and deform during cutting. Using the right blade and cutting technique is essential to ensure accurate and consistent results.

Advantages of Using Steel Rule Dies

Steel rule dies offer several advantages over other cutting methods, making them a preferred choice in many industries. One of the primary benefits is precision. Steel rule dies can produce intricate and accurate cuts, ensuring that each piece meets exact specifications.

Another advantage is efficiency. Steel rule dies enable high-speed production, reducing the time required to cut materials. This efficiency translates to cost savings, as manufacturers can produce more items in less time.

Versatility is also a significant benefit of steel rule dies. These tools can cut a wide range of materials, from thin paper to thick foam, making them suitable for various applications. This versatility allows manufacturers to use a single tool for multiple processes, increasing flexibility and reducing the need for multiple cutting tools.

Applications of Steel Rule Dies

Steel rule dies are used in various industries, each with unique requirements and standards. In the packaging industry, steel rule dies are used to cut and shape cardboard, creating boxes, cartons, and other packaging materials. The precision of steel rule dies ensures that each piece fits together perfectly, providing secure and attractive packaging.

In the automotive industry, steel rule dies are used to cut gaskets, seals, and other components. These parts must meet strict quality standards, and steel rule dies provide the accuracy needed to ensure that each piece performs as expected.

The electronics industry also relies on steel rule dies for cutting and shaping materials used in electronic devices. These dies create precise cuts required for components such as circuit boards, ensuring that each piece fits together seamlessly.

Innovations in Steel Rule Die Making

The field of steel rule die making has seen several innovations in recent years, driven by advances in technology and materials. One significant innovation is the use of computer-aided design (CAD) software. CAD enables designers to create highly detailed and accurate die designs, improving the precision and efficiency of the die-making process.

Another innovation is the use of laser cutting technology. Laser cutters can produce highly intricate and precise cuts, allowing for more complex die designs. This technology also reduces the time required to create dies, increasing efficiency and reducing costs.

Materials used in steel rule dies have also seen improvements. Advances in steel alloys have led to stronger and more durable blades, increasing the lifespan of the dies. These materials also improve the quality of cuts, ensuring that each piece meets exact specifications.

Quality Control in Steel Rule Die Making

Quality control is a critical aspect of steel rule die making, ensuring that each die meets the required standards and performs as expected. The first step in quality control is inspecting the raw materials used in the die-making process. High-quality steel and base materials are essential for creating durable and accurate dies.

During the die-making process, each step is carefully monitored to ensure accuracy. Precision machines and tools are used to shape and bend the steel rule, and regular inspections are conducted to identify any deviations from the design specifications.

The final step in quality control is testing the die. This involves using the die to cut sample materials and inspecting the results for accuracy and consistency. Any imperfections are addressed before the die is approved for use, ensuring that each die performs as expected.

Challenges in Steel Rule Die Making

Despite the advantages and innovations in steel rule die making, several challenges remain. One challenge is maintaining precision and accuracy throughout the die-making process. Even minor deviations can affect the performance of the die, requiring careful attention to detail and regular inspections.

Another challenge is the wear and tear on the dies. Steel rule dies are subjected to significant pressures during the cutting process, leading to wear and deformation over time. Regular maintenance and replacement of worn parts are essential to ensure the longevity and performance of the dies.

The increasing complexity of die designs also presents a challenge. As manufacturers demand more intricate and precise cuts, the design and creation of dies become more complex. Advanced technologies such as CAD and laser cutting are essential to meet these demands, but they also require skilled technicians and designers.

The Role of a Steel Rule Die Maker

The steel rule die maker plays a vital role in the manufacturing process, combining technical skills with creativity and precision. These professionals are responsible for designing, creating, and maintaining steel rule dies, ensuring they meet the required standards and perform as expected.

A steel rule die maker must have a deep understanding of materials, cutting techniques, and design principles. They must also be skilled in using advanced tools and technologies, such as CAD software and laser cutters.

In addition to technical skills, a steel rule die maker must have strong problem-solving abilities. They often encounter challenges during the die-making process and must find creative solutions to ensure the final product meets the required specifications.

Training and Certification for Steel Rule Die Makers

Becoming a skilled steel rule die maker requires extensive training and education. Many professionals in this field start with an apprenticeship, gaining hands-on experience under the guidance of experienced die makers. Apprenticeships provide a solid foundation in the betterthistechs technical skills and knowledge required for the job.

Formal education is also essential for aspiring die makers. Many technical schools and community colleges offer programs in die making and related fields, providing students with the theoretical knowledge and practical skills needed for the profession.

Certification is another important aspect of becoming a steel rule die maker. Several organizations offer certification programs, providing validation of a die maker’s skills and knowledge. Certification can enhance job prospects and provide opportunities for career advancement.

Future Trends in Steel Rule Die Making

The future of steel rule die making is likely to be shaped by several trends and advancements in technology. One significant trend is the increasing use of automation in the die-making process. Automation can improve efficiency, reduce costs, and enhance precision, making it an attractive option for manufacturers.

Another trend is the development of new materials and technologies. Advances in steel alloys and cutting techniques are likely to lead to more durable and precise dies, improving the quality and efficiency of the cutting process.

The integration of digital technologies, such as CAD and laser cutting, is also expected to continue. These technologies enable more complex and accurate die designs, meeting the growing demand for precision in the manufacturing industry.

Conclusion

Steel rule die making is a critical aspect of modern manufacturing, enabling precision and efficiency in the production process. From the initial design to the final assembly, each step requires meticulous attention to detail and advanced technical skills.

Understanding the role and importance of steel rule dies can help manufacturers improve their processes, reduce costs, and enhance the quality of their products. By staying informed about the latest trends and advancements in die making, businesses can ensure they remain competitive in an evolving industry.

Keep an eye for more news & updates on InternalInSider!