In today’s fast-paced manufacturing landscape, ensuring product quality while maintaining production efficiency is paramount. One of the critical areas requiring precision and attention is door panel inspection. With the advent of Machine Vision AI, automating this process has become not only possible but also highly effective. By integrating surface defect detection capabilities, manufacturers can enhance quality control, reduce costs, and achieve operational excellence. This article explores the transformative role of Machine Vision AI in automating door panel inspection.

Challenges in Door Panel Inspection

The door panel, a vital component of vehicles, appliances, and industrial equipment, must meet stringent quality standards. However, traditional inspection methods come with numerous challenges:

- Manual Inspection Fatigue: Human inspectors are prone to fatigue, leading to inconsistent results and missed defects.

- Complex Defects: Surface imperfections like scratches, dents, and uneven coatings require meticulous scrutiny, which is difficult to achieve manually.

- High Volume Production: Keeping up with the inspection demands of high-speed manufacturing lines often results in bottlenecks.

- Subjective Judgments: The variability in human judgment can lead to non-standardized inspection results.

To overcome these issues, manufacturers are turning to automated inspection systems powered by Machine Vision AI.

What is Machine Vision AI?

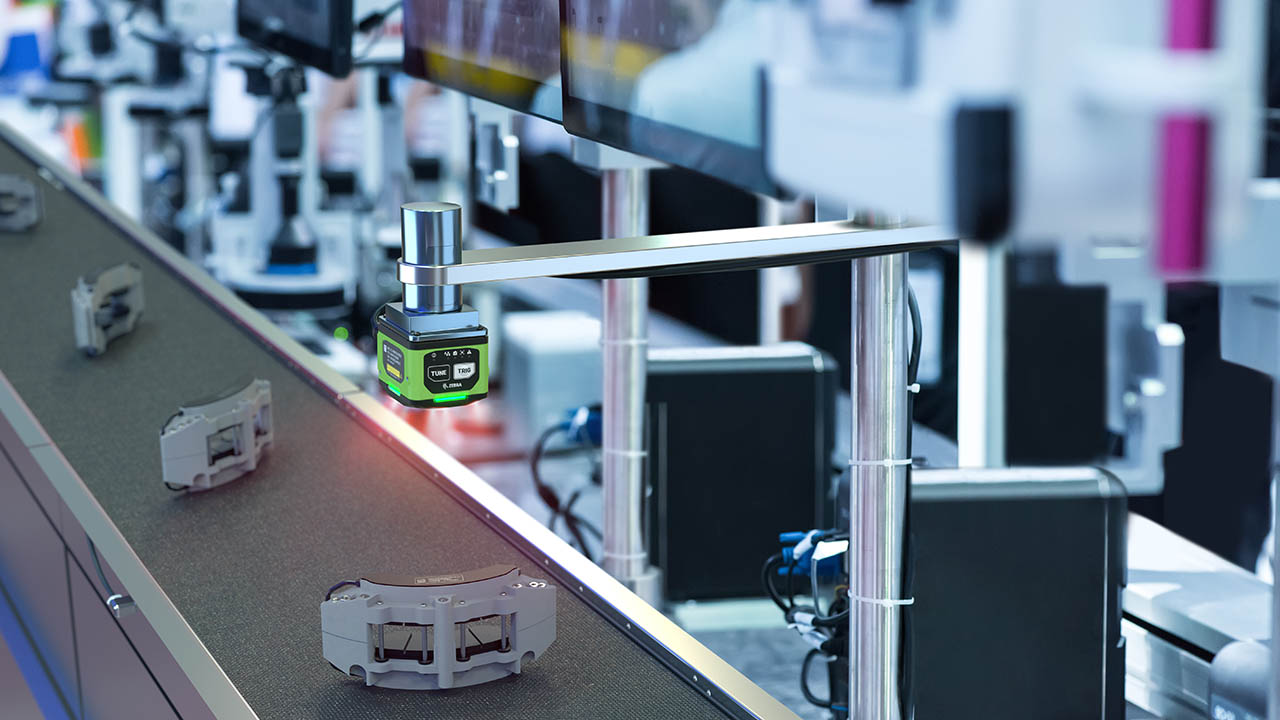

Machine Vision AI combines advanced imaging systems with artificial intelligence to mimic human vision and decision-making capabilities. These systems are equipped with high-resolution cameras, intelligent software, and deep learning algorithms. By analyzing images pixel by pixel, Machine Vision AI can identify even the minutest defects on door panels.

How Machine Vision AI Works in Door Panel Inspection

The implementation of Machine Vision AI for door panel inspection involves several stages:

1. Image Acquisition

High-resolution cameras capture multiple images of the door panels. The imaging setup includes specialized lighting to eliminate shadows and highlight surface imperfections.

2. Preprocessing

Captured images are preprocessed to enhance clarity. Noise reduction, contrast adjustment, and alignment are applied to ensure the AI system receives the cleanest possible data.

3. Defect Detection

AI algorithms analyze the images for surface defects, such as:

- Scratches

- Dents

- Paint inconsistencies

- Burrs or protrusions

- Misalignments

4. Classification

Once defects are detected, they are classified based on severity. Cosmetic defects may be acceptable, whereas critical defects require immediate attention.

5. Reporting and Action

Inspection results are displayed in real-time on dashboards. The system can trigger automated alerts or sort defective panels for further review.

Advantages of Automating Door Panel Inspection

- Enhanced Accuracy

Machine Vision AI delivers unmatched precision, detecting defects that are often missed by manual inspection. - Increased Speed

Automation ensures rapid inspection, enabling manufacturers to keep pace with high production volumes. - Cost Savings

Reducing manual labor and minimizing defect-related recalls significantly lower operational costs. - Consistency and Reliability

Unlike human inspectors, AI systems maintain consistent performance without fatigue or bias. - Data-Driven Insights

Inspection data collected over time can be analyzed to identify recurring defects and optimize manufacturing processes.

Surface Defect Detection: A Game-Changer

The core feature of Machine Vision AI systems is their ability to perform surface defect detection with exceptional accuracy. These systems utilize deep learning to differentiate between acceptable variances and critical defects. For instance:

- Scratches and Dents: Detected through pixel-level analysis.

- Paint Imperfections: Identified using color and texture recognition algorithms.

- Welding Defects: Analyzed through pattern matching and edge detection.

Key Technologies Powering Machine Vision AI

- High-Resolution Cameras

Capable of capturing intricate details, these cameras form the backbone of the system. - Advanced Illumination Systems

Structured lighting setups ensure consistent image quality, eliminating shadows and reflections. - Deep Learning Models

Trained on vast datasets, these models learn to identify and classify defects with high precision. - Edge Computing

Processing data locally reduces latency and ensures real-time decision-making. - Integration with Existing Systems

Machine Vision AI systems can seamlessly integrate with programmable logic controllers (PLCs) and other automation tools.

Applications of Automated Door Panel Inspection

The versatility of Machine Vision AI enables its application across various industries:

- Automotive: Ensures defect-free door panels for cars and trucks.

- Appliances: Inspects panels for refrigerators, ovens, and washing machines.

- Aerospace: Maintains stringent quality standards for aircraft door panels.

- Construction: Evaluates door panels for commercial and residential buildings.

Implementation Process: Automate Door Panel Inspection

Step 1: Needs Assessment

Evaluate the specific inspection requirements, such as defect types, panel materials, and production speeds.

Step 2: System Design

Develop a customized solution, including camera placement, lighting setup, and AI model configuration.

Step 3: Training and Calibration

Train the AI system using a dataset of defect-free and defective panels. Calibrate the system to meet specific quality standards.

Step 4: Deployment

Integrate the Machine Vision AI system into the production line, ensuring seamless operation with minimal disruption.

Step 5: Monitoring and Optimization

Continuously monitor system performance and refine algorithms to adapt to new defect types or production changes.

Future Trends in Door Panel Inspection Automation

The field of Machine Vision AI is evolving rapidly, with emerging trends poised to enhance its capabilities:

- 3D Vision Systems: Enable inspection of complex panel geometries with high accuracy.

- Cloud Integration: Facilitates remote monitoring and data analysis.

- Augmented Reality: Provides real-time visual feedback to operators for better decision-making.

- Predictive Maintenance: Uses inspection data to forecast equipment failures and prevent downtime.

Why Choose Machine Vision AI for Door Panel Inspection?

Automating door panel inspection with Machine Vision AI is a strategic investment for manufacturers aiming to stay competitive in today’s market. By leveraging the power of surface defect detection, businesses can:

- Enhance product quality

- Reduce operational costs

- Improve customer satisfaction

- Achieve compliance with industry standards

The integration of Machine Vision AI in door panel inspection is revolutionizing manufacturing. By automating surface defect detection, manufacturers can achieve unparalleled accuracy, speed, and efficiency. As the technology continues to advance, its applications and benefits will only expand, making it an indispensable tool for quality assurance.

If you’re looking to automate door panel inspection, investing in Machine Vision AI systems is the way forward. With its ability to detect defects, provide real-time insights, and adapt to complex manufacturing environments, this technology is shaping the future of automated quality control.

Stay in touch to get more news & updates on Internal Insider!