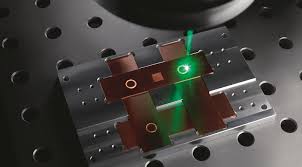

Laser welding is an advanced generation of lithium batteries. These batteries are standard in electric-powered automobiles, smartphones, and one-of-a-kind digital devices. Laser welding performs an essential function in production, supplying battery reliability and performance. Here is the way to use laser welding with lithium batteries.

1. Joining Battery Cells

Lithium batteries are made up of many small cells. These brackets ought to be securely connected for proper operation. Laser welding is used to sign up for those cells. It gives a robust and correct connection that contributes to battery life and efficiency.

2. Connecting Tabs and Terminals

In a lithium battery, tabs, and terminals join the cell to the device that powers it. Laser welding is ideal for this job as it permits smaller, greater correct welds. This stabilizes the connections, lowering the risk of strength loss or failure. Explore more

3. Sealing Battery Cases

Lithium batteries must be sealed tightly outside to save moisture and air from entering. Laser welding covers these troubles as it provides a smooth hermetic floor. This helps guard the battery from damage and extends its life.

4. Ensuring Safety

Lithium batteries can only be safe if made well. Poor connections or seals can also cause overheating or cracking. Laser welding facilitates keeping away from those troubles by making sure that each part of the battery p.C. It is correctly assembled. This makes the battery safe to apply.

5. Improving Production Speed

Laser welding is faster than conventional methods and gives faster battery life. This is essential for battery producers who need to quickly provide massive quantities of batteries. Faster battery production also approaches lower costs, making batteries more costly.

6. Enabling Lightweight Designs

Lithium batteries, specifically those used in electric motors, want to be lightweight lightweight. Laser welding allows you to use thinner materials without sacrificing power, resulting in smaller but extra-green batteries.

Types of Laser Welding

1. Conduction Mode Welding

- How it works: This approach uses much less power to mold the surface of the mixture.

- When used: Usually for skinny additives and steel tabs in lithium batteries, where deep welding isn’t required.

2. Keyhole Mode Welding

- How it works: This method uses a lot of strength to create a small, deep hollow (keyhole) in the material. As the material cools, the secret is filled, creating a robust bond.

- Use Time: This is good for complicated components, including round batteries, where thicker and deeper welds are required.

3. Hybrid Laser Welding

- How it works: This method combines laser welding with different strategies, including arc welding, for greater long-lasting and faster welding.

- Time of use: Used while velocity and performance are critical, which includes mass battery production.

Uses of Laser Welding in Lithium Batteries

1. Joining Battery Cells

- Why Important: The lithium battery cells should be correctly connected for proper battery operation. Laser welding is best for this activity because it provides a robust and correct connection.

2. Connecting Tabs and Terminals

- Why it’s Important: Tabs and terminals connect battery cells to the strength delivered. Laser welding strengthens these connections, decreasing energy losses.

3. Sealing the Battery Case

- Why Important: The exterior of a lithium battery must be sealed tightly to prevent water and air from entering. Laser welding makes the battery clean and hermetic, protecting the battery from damage.

4. Attaching Cooling Plates

- Why it matters: Some lithium batteries, particularly electric cars, need cooling plates to prevent overheating. Laser welding securely connects these plates without affecting the battery cells.

5. Making Lightweight Batteries

- Why It’s Important: Laser welding permits you to apply thinner surfaces without sacrificing strength. This facilitates the creation of making lightweight batteries perfect for electric-powered automobiles and other transportable gadgets.

Advantages of Laser Welding in Lithium Batteries

- High Precision

- Why It’s Important: Laser welding offers exquisite precision, which is essential when dealing with small elements in lithium batteries. This accuracy contributes to a more robust and more accurate connection, resulting in better battery life.

2. Strong and reliable relationships

- Why It’s Important: Laser-welded connections are more potent and durable. This is essential for lithium batteries because they ought to withstand vibration, temperature fluctuations, and lengthy use intervals without degradation.

Disadvantages of Laser Welding in Lithium Batteries

- High Initial Cost

- Why It’s a Problem: The system needed for laser welding is steeply-priced. This high cost may be a barrier for smaller producers or those just beginning to produce lithium batteries.

2. Professional people are required

- Why It’s a Problem: Operating a laser welding device requires substantial schooling and enjoyment. Finding professional employees may be challenging; schooling can take money and time.

Conclusion

Laser welding is critical in the manufacturing of lithium batteries. It helps join cells, connect tabs, and take a look at bins, ensure security, improve production pace, and permit lightweight programming. As the call for lithium batteries increases, laser welding will continue to play a vital role in their manufacture, making them more secure, more dependable, and more green.