We all can see how much the world is evolving. Every single day, we hear about new innovation in old technologies or new inventions.

Many businesses and industries are affected by these technologies. One of the most famous thing in this debate is actually ‘AI.’

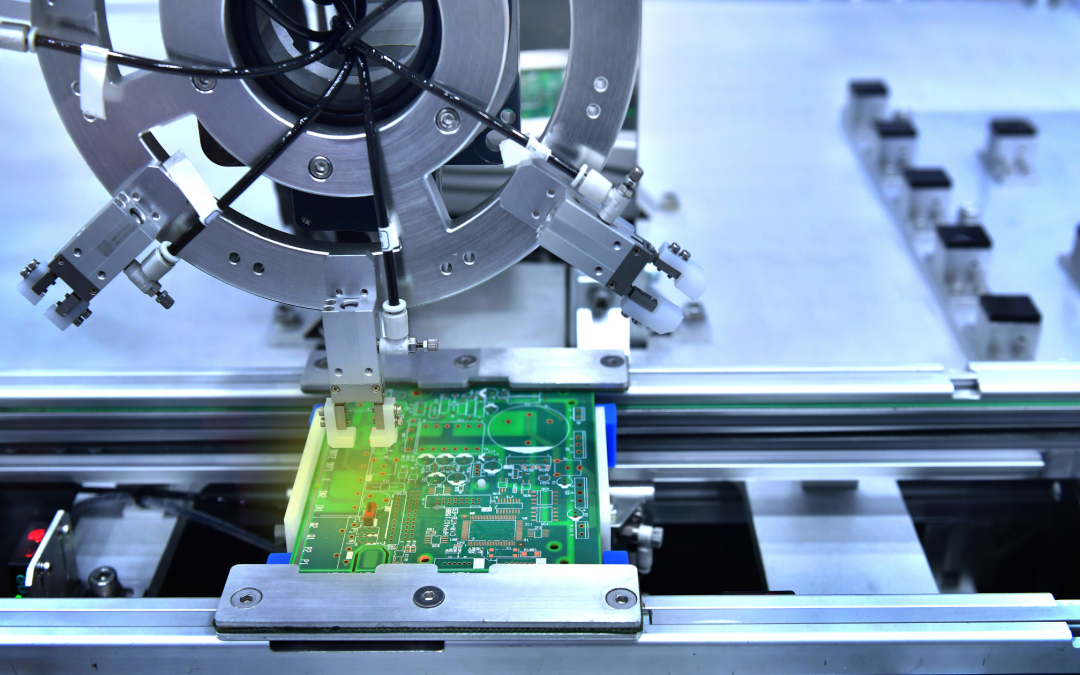

But today, we’ll have a look at new technologies and future trends that might change the game of PCB in the future. So, let’s go:

Technological Changes and Their Affects PCB Manufacturing

- Wave of Recyclable Stuff

One of the biggest concerns of today’s world is pollution and one of the biggest reasons behind that waste is electronics or e-waste. That’s why a wave of trends like ‘Go Green’ came in and are still booming.

Not just the PCBs manufacturing industry, but all industries that somehow had relationships had to take steps back and bring ways to start manufacturing environmentally friendly stuff.

The most credible way to tackle waste and pollution is by manufacturing recyclable or biodegradable PCBs. The best method suggested was using fiberglass as substrate in the manufacturing of PCB.

- Use of Advanced Material

Due to making stuff with red hot material, whenever a law passes or a trend comes in, PCB manufacturers are the one who gets backlash first.

Whether a social movement comes or a protest happens against industries, PCB is always in the first row. For example, the trend of spreading news about lead being a harmful substance isn’t old.

As soon as the trend reached social media, people started demanding lead-free manufacturing of everything that somehow included it and PCB was one of them.

If you are planning to become a PCB manufacturer, be ready to acknowledge this kind of situation and clever enough to come up with a solid solution.

- Rumors about Autorouter in PCBs

If you are new to PCB industry, you need to know that autorouter wasn’t a permanent part of PCBs in past. But now, every PCB must have it.

The autorouter is a tiny device that’s fitted in PCB to track every step it takes. In other words, it gives direction to electronic functions on the board to create a diagram of layout of its characteristics.

But how is it helpful?

It actually makes automation process easier. But the truth all manufacturers know is that it’s extremely time taking and difficult to plant an autorouter. It takes more time than it saves for the automation process.

Now, there are rumors that manufacturers are deciding to eliminate routers from manufacturing. But it has become a compulsory part of PCBs and public wants. What do you think will happen?

- Demand for Miniature and Smart Devices

After using bigger smartphones, the public has been rapidly switching to smartwatches and mini smartphones. And we all know that it’s not that easy to manufacture miniature PCBs.

Moreover, if you want perfection, you have to spend a good amount of extra money because for that, you’ll need roger’s PCB material instead of FR4.

- Medical Equipment

In the past few decades, humans have been paying attention to every industry except medicine. That’s why inclusion of digital technology took a bit too long to come into medical world.

But as soon as it made its first step, the demand never stopped. The industry kept demanding and developers kept providing. The thing you now need to understand is that this demand-supply loop is never-ending.

- Board Cameras

PCB cameras or board cameras are some of the most useful inventions in digital world in recent times. By adding lenses, aperture and image sensors to circuit boards, engineers gave world a chance to take digital images and videos. From dashboard cameras to surveillance cameras and medical equipment, they all are examples of innovation in PCB technology.

- Public’s Focus on Flexible PCBs

After 2015, when technology started to boom again at a great pace, in PCB industry, a new concept was born and it was flexible PCBs. It became so popular in next to no time that experts predicted it to become the biggest market for PCBs.

Although it’s still in a growing state, reports have proved that it’s fastest growing industry of PCBs. It was projected to become a huge market of 27 billion USD by 2022.

If you don’t know how to handle flexible PCBs and their production, you need to do it now because many industries have already started making flexibility a real issue like:

- Medical Equipment

- LED Lightings

- Curved Monitors

- Rotatable Displays

- Inclusion of 3D Technology

Final Takeaway

Just like any other industry, PCB manufacturing will also keep evolving and technology will keep hitting hard. Your job is not to make excuses and blame technology for any circumstances. Those will be successful who will change themselves along with technology. And the shocking part of it is that only a few manufacturers like UETPCB do that.

Read Now: Internal Insider